How to save energy by understanding the difference on data and information.

When it comes to monitor and analyse performance of Refrigeration, Air Conditioning and Heat Pumps (HVACR systems) to save energy, two comments are common. Even when there are obvious problems in the system:

1. We already have all “information” so, what is the difference between ClimaChecks system/analysis and the present BMS/BAS/SCADA-systems?

2. How long do we need to measure performance to be able to save energy and avoid failures.

To answer these questions, it is crucial to understand the difference between data and information. Today it is getting common to collect large amount of data from HVACR systems. However, collecting data is not the same thing as having actionable information, this can’t be emphasised enough.

With the right information it is possible to see performance on different components, in real time. Data points like, temperature, pressure, and power measure on its own will not give this as they vary continuously over a wide range.

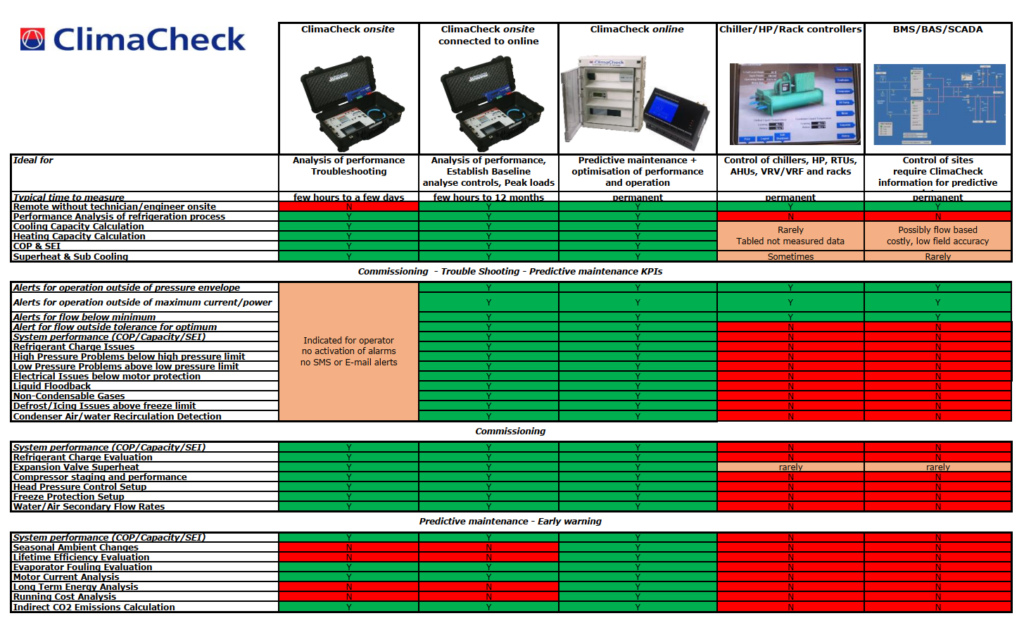

ClimaCheck have delivered “stand-alone” systems since 2007 to do performance analysis in the cloud. With a higher acceptance for IoT and Industry 4.0 more and more data is collected today, so it is often not necessary to add a stand-alone system to collect data. However, it might be easier than updating old BMS systems in some situations. The important part is that data is sent to the “cloud” for analysis of relevant performance KPIs, so today both a gateway and API solution is available.

When data is turned into information?

When data is analysed and the actionable information is available, the first crucial step is taken. However, a plan and goal, is essential. Without a structure to use the information, there is a risk that it is used only to explain failures instead of preventing them.

To deep dive in KPI’s and differences between ClimaCheck analysis and conventional BMS/SCADA. You can read more here.

Regarding the plan and goal, if it is to:

1. Collect data and hope that someone looks at it and uses it.

or

2. Collect and analyse data to get actionable information from the analysis to work with energy optimisation and predictive maintenance as a part of your sustainability work?

If your answer was nr 2, keep on reading.

The goal; energy optimisation and predictive maintenance

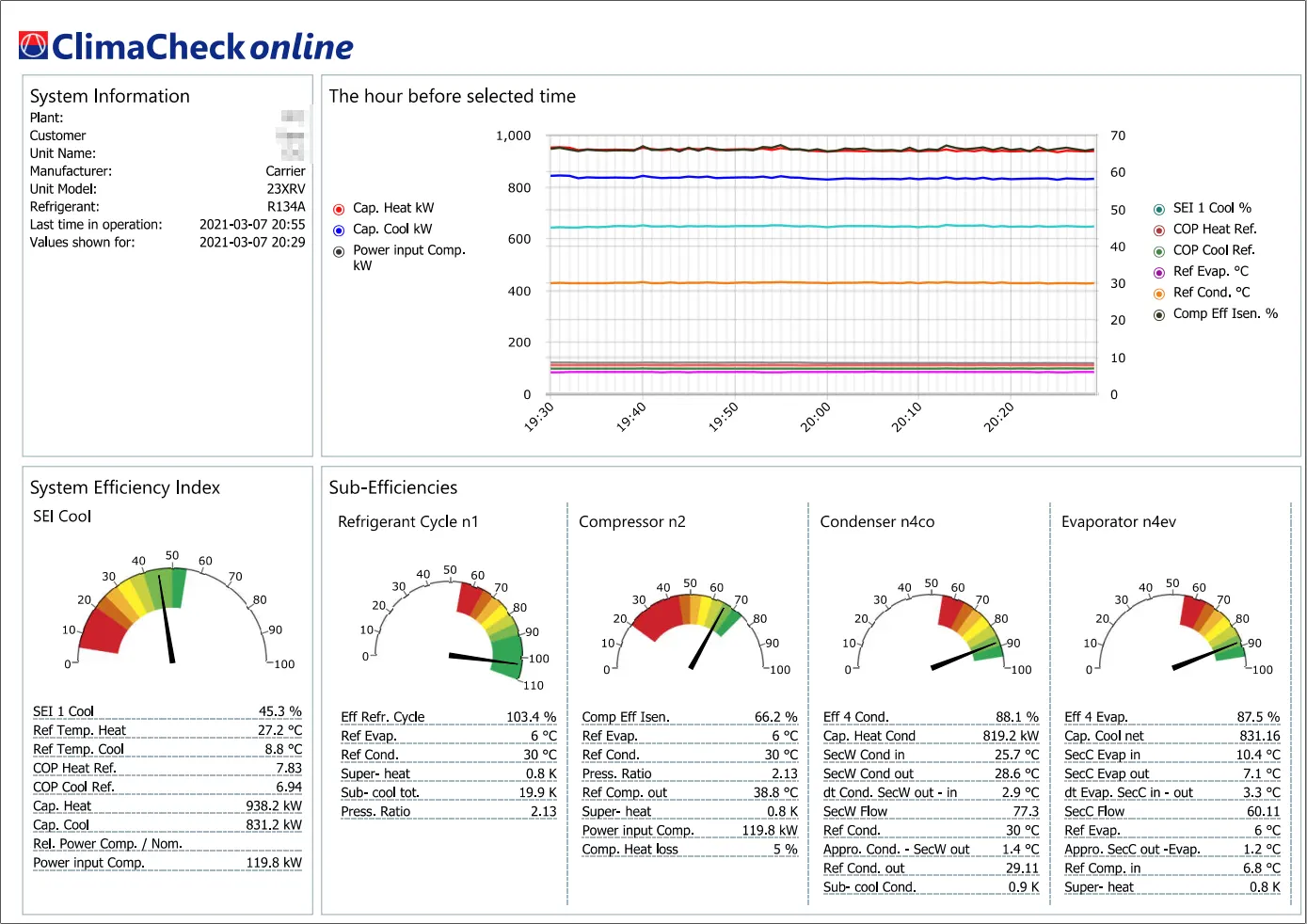

The ClimaCheck method is internationally recognised as the “Internal method”, which analyse system performance and all relevant KPIs. The information from the analysis is presented for different levels to enable optimisation, e.g., System Efficiency Index (SEI) for total system and sub efficiencies that result in actionable information, which makes it possible to detect and fix deviations as soon as they occur. This is a crucial for predictive maintenance and energy optimisation.

How about the time?

Initially we had two questions, and now we know the difference on information and data. The second part is how long do you need to measure performance to get actionable information.

This is based on the goal, if the goal is to troubleshoot e.g. a heat pump or chiller a temporary measurement can be done with ClimaCheck onsite. It takes from 30 minutes to connect and gives you performance information in real time. With a shorter measurement (a few hours to a few days), it is possible to see system performance during the period and conditions occurring to take action when needed.

However, the goal is often to be energy efficient over time and reduce cost of reactive maintenance (failures). This increases the value of accountable information and require a structure for energy optimisation and predictive maintenance. This relies on that performance information is continuously available, which makes ClimaCheck online the perfect match. For predictive maintenance, 24/7 monitoring of performance is necessary.

HVACR operations are affected by many factors, and it take months to analyse all operating conditions as weather and loads change. Basically, if the system is operating in a climate zone where temperatures can be between minus 20°C and plus 30°C, you want to record as many as these as possible. It is also a fact that things like leaks and changes of controls happen over time, so it is only continuous analysis that give you the possibility to get early warning when a fault start to occur and allow you to correct them before they cause failures and high energy costs.

What about the BMS/BAS/SCADA-system? In most cases these are used to visualise data and sometimes to control the system or parts of it. Most modern systems can distribute data (integrate with) with e.g. ClimaCheck for additional analysis. When data is analysed, information can be sent back from ClimaCheck online to raise the level of information in the BMS system. At the same time as all KPIs are monitored 24/7 for deviations by ClimaChecks FDD. A unique function that is specifically developed to monitor performance of refrigeration processes on component level based, on more than 15 years of experience covering thousands of systems.

Conclusion!

Being energy efficient is not a quick fix, information and time is crucial.

Today it is not enough to collect and visualise basic data points like temperature, pressure, and/or power consumption, the bar needs to be risen. It is way too time consuming to manually calculate the raw data into actionable information without a third part analysis. However, that analysis is easy to add today.

When the analysis is implemented, the necessary information should be available and used. If the information is available but not used, it makes little to no sense to have it. To avoid this situation, we have prepared a guide for you (download here). In the guide you will find the nine-step method “dDOP” (Data Driven Energy Optimisation and Predictive Maintenance) which helps organisation that have HVACR systems to include them in their sustainability work. As well as it makes sure that all the right data is collected and used to utilise predictive maintenance!

So, to answer the first two questions. If you have actionable information, it should be possible to detect deviations when they appear. And there should be a routine (based on a plan) to fix the problem. And timewise, “to measure is to know” the second you don’t analyse system performance you don’t know what happens.

The saving potential is often 10% to 30%, in HVACR systems which consumes 30% to 60% of many buildings total energy. Making the ROI to implement ClimaCheck, very short. We have helped many leading organisations to reach a higher level of sustainability. If you want to take the next step, we are happy to help! Feel free to book a demo.

More news

Glad Påsk önskar ClimaCheck!

Vi passar på att önska er alla en riktigt glad påsk!

ClimaCheck 20 Years and New Logo!

To celebrate our first 20 years, we take the opportunity to update our logo. If you follow us on social media or subscribe to our newsletter, then you have probably already noticed the logo, as it has gradually made its appearance.

Gulf Engineering seminar – February highlight

We want to extend a big thank, to ClimaCheck Partner, Gulf Engineering, for hosting a well-attended and arranged seminar that fostered engaging discussions and productive meetings.