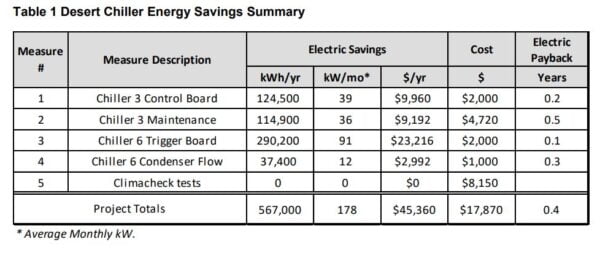

Payback (ROI) less than one year.

Improved performance

Executive Summary

ETC Group conducted chiller testing using a portable ClimaCheck chiller analyzer at Desert Medical center on chillers 3, 5, and 6. Sections 2 and 3 include details for each measure.

- Measures 1, 2, and 4 have been identified through ClimaCheck and have yet to be implemented

- Measure 3 below was identified because Chiller 6 failed. Banner requested JCI to perform these repairs which occurred after our testing.

- However, ClimaCheck flagged this chiller as having a high kW/ton. Continuous monitoring of this chiller would have identified the kW/ton remaining high even after fixing measure 4 and the savings potential would justify further analysis from a JCI technician

Important Findings

Chiller 5 is 10% to 15% More Efficient than Chillers 3 and 6

Chiller 5 tested from 10% to 20% more efficient than the other chillers. The issues identified below

provide details for these differences.

Replace the Chiller 3 Control Board

Issues

Chiller 3 needs an upgraded control board. JCI’s technician Jeremiah Yanez stated that chiller 3 has an older control board than chillers 5 and 6. This control board doesn’t have the processing speed to maintain a constant leaving chilled water supply temperature.

Chiller 3 operated with a cyclic pattern of its inlet vanes opening and closing on a 7 minute cycle. A chiller modulates its inlet vanes as the first response to maintain a constant leaving chilled water supply temperature. With a constant 47°F leaving chilled water supply temperature set point, the chillers delivered water between 46.5°F and 47.5°F. As the VFD speed remained steady, the inlet vanes cycled from full open to around 85% closed.

Next Steps

Replace the control board on Chiller 3 and ensure its control algorithm is tuned to keep the inlet vanes fully open while slowing down the VFD speed.

JCI’s technician estimated the new control board would cost $2,000. Labor for this work is covered with Banner’s existing service contract with JCI.

Chiller 3 Refrigerant Level and Evaporator Tube Fouling

Chiller 3 has two maintenance issues:

- Low refrigerant levels o High superheat (~ 4°F) and low sub-cool (~5°F) indicate low refrigerant levels in Chiller 3

- High approach temp (3.2°F) indicates the evaporator tubes have poor heat transfer (either from scaling or oil on tubes)

Next Steps

- Remove the refrigerant from chiller 3. Weigh the total refrigerant removed and refill the chiller

with the required amount.- Take a sample of the refrigerant and test for the presence of air and oil.

- During annual maintenance, clean the evaporator barrels.

We estimated the chiller is short 400 lbs of refrigerant and refrigerant costs $7/lb. We included

another 16 hours of labor for tube cleaning.

Chiller 6 Trigger Board Replaced

Issues

During testing, we observed that Chiller 6 operated approximately 21% less efficient than chiller 5. Shortly after our testing, Chiller 6 failed on a “VFD single phase failure”. Since this time, Banner personnel had JCI fix the chiller. The trigger board was malfunctioning. This has been replaced and chiller 6 now operates at the same efficiency as chiller 5.

Next Steps

JCI has already replaced the trigger board. We estimated that this cost Banner $2,000.

Increase Chiller 6 Condenser Water Flow

Issues

Chiller 6 has the highest condenser refrigerant pressure vs the other chillers. This is because it has the warmest leaving condenser water. All of this is the result of Chiller 6 receiving about 14% less condenser water flow than chillers 3 and 5.

All of these chillers have a modulating valve that controls flow through the condensers to maintain a constant 9°F temperature differential on the water in and out with a minimum flow of 3,100 GPM/chiller. During testing, the actual dT was around 6°F to 7°F which meant the minimum flow measurement was

controlling the flow.

Next Steps

Calibrate Chillers 6 condenser water flow meter. It currently reads about 14% too low. We have estimated that calibration of the flowmeter will cost $1,000.

Project details

Client: Banner Desert Medical Center

Building type: Hospital

Project Manager: ETC Group

System: 3 Chillers

Other projects