Operating cost decreased with 5000 Euro/Year

Removed high risk of future compressor failures.

Customer case

Air conditioning inspections, UK

State of the art inspections and audits Requirements on performance inspections are being implemented on many markets and incentives for recommissioning introduced. Traditional methods for measuring performance involve flow measurements that cannot provide accurate and stable measurements, which makes them not cost-effective.

ClimaCheck offers a solution that identifies any deviation from optimal performance on component level and validates performance in an un-biased way

without input from manufacturer’s data.

Thousands of inspections have been carried out showing that savings of 10-40 % can be achieved without significant investments.

Cost effective visualisation of performance with data on component level offers new possibilities to validate performance and optimise systems.

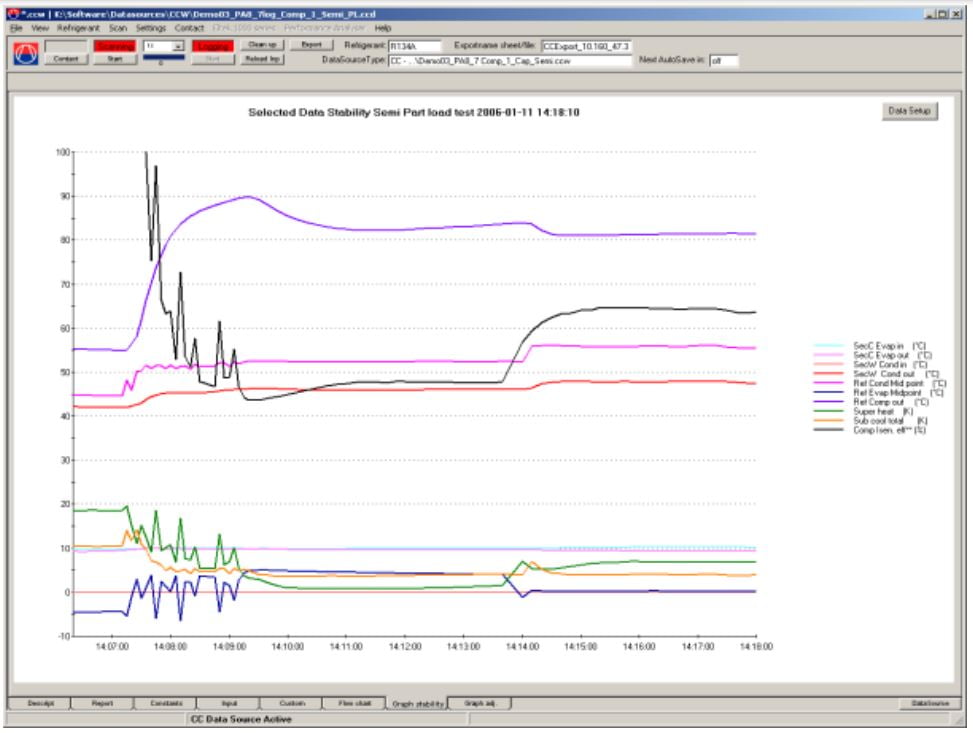

The example above, documents the performance of a chiller with a compressor with inefficient part-load operation. The measurements pinpointed that

insufficient control of super heat at part-load operation was the cause of several earlier unexplained compressor failures. ClimaCheck identified the shortcomings of the expansion valve

Result

Time used for measurement (inspection) was 2 hours and part load solenoids that was not beneficial for this plant was deactivated:

- Annual operating cost decreased with 5000 Euro

- Removed high risk of future compressor failures.

To learn more you can contact Business Edge Ltd or ClimaCheck

Download case

Other projects