Automated Fault Detection and Diagnostics: A Prerequisite for Predictive Maintenance

Introduction to Automated Fault Detection and Diagnostics

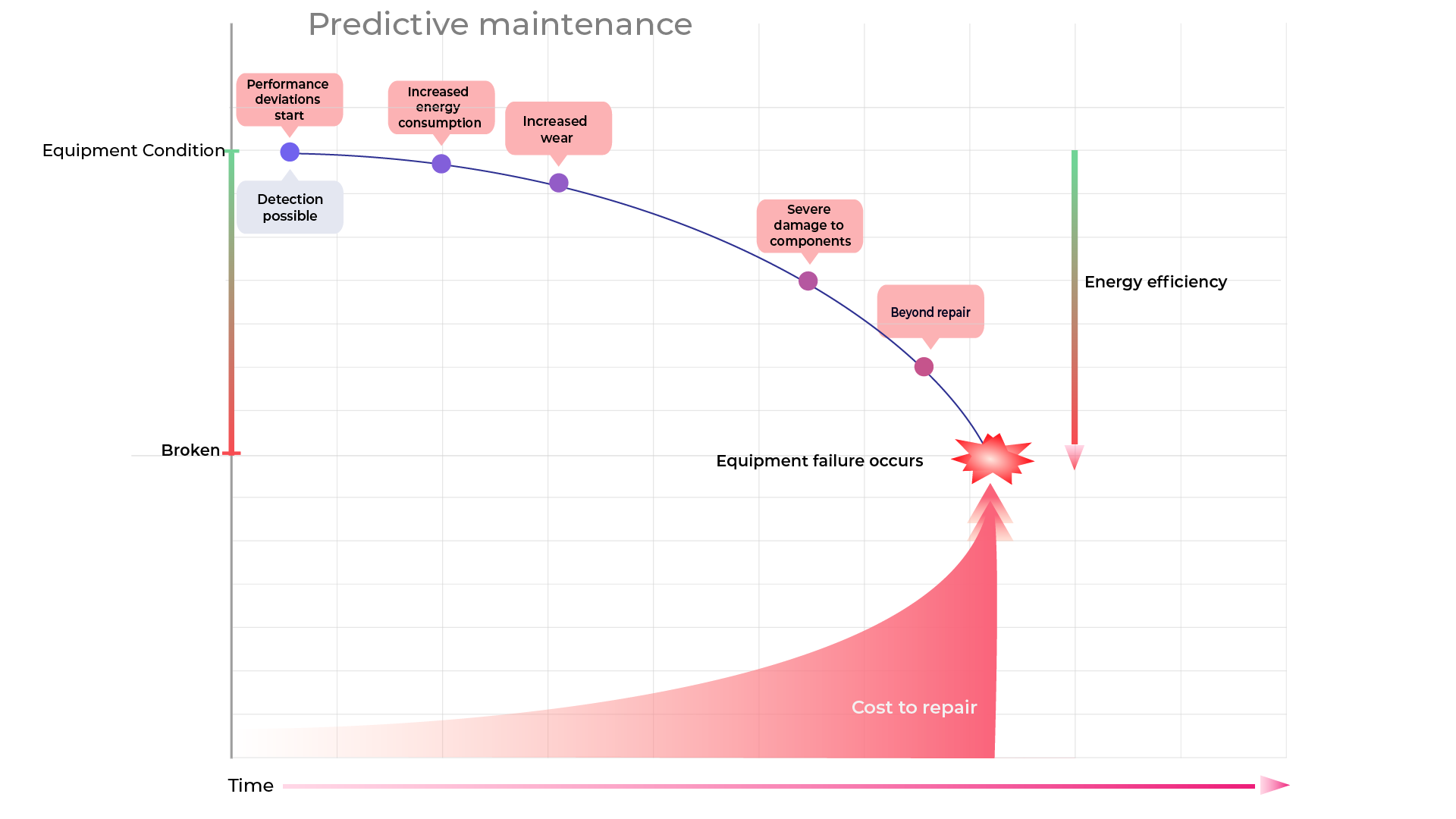

The core of Automated Fault Detection and Diagnostics (AFDD) is to identify problems and deviations automatically before they cause performance drift, high energy bills and escalate to system failures that trigger an alarm. Working predictively with the help of AFDD is beneficial in many ways; it will save money, time, frustration and reduce energy consumption.

With an increasing focus and acceptance for IoT, more sensors are installed than ever. This generates large amount of data; however, it is raising many questions such as:

- Do we use the data?

- How can we use the data?

- Was it worth the investment?

- Why do we still have problems?

These questions highlight a common problem that many companies face today: large amount of data isn’t enough.

This is where Industry 4.0 and modern analytical methods changes the game. Efficient ways of work such as Predictive Maintenance (PdM), assisted by Automated Fault Detection and Diagnostics (AFDD) based on performance analysis makes it possible to use the collected data efficiently.

By analysing the collected data with state-of-the art methods and get access to actionable information, it is possible to identify and mitigate inefficiencies and failures in an early stage. Air conditioning, refrigeration, and heat pump (HVACR) systems are no exception but are lagging long behind other industries in acceptance of Predictive Maintenance.

The opportunity with Automated Fault Detection and Diagnostics within HVACR

HVACR systems can be complex and are often business critical, however their performance is almost always taken for granted as long as there are no complaints and “the right temperature” is reached. Today this creates multiple levels of cost, which often are accepted as they have always been there. To be sustainable and energy and cost efficient this needs to change.

By analysing the available data and utilise a system with good Automated Fault Detection and Diagnostics (AFDD) functionality many of the very common problems can be detected early and failures and down-time avoided.

Typical problems can be:

- System failure during a heat wave or cold spell due to degradation of performance

- Refrigerant leaks or over-charge

- Compressor degradation long before it leads to failures

- Condenser/evaporator fouling

- Not optimised flows

- Unnecessary start and stops

- Unstable operation

- Increased energy consumption

- Any loss of capacity or performance

These problems create unnecessary costs in many forms such as, increased energy consumption (often with 10-30%) as well as increased wear and breakdowns, which in turn increase the demand for unplanned maintenance .

“Business as usual” within maintenance in the HVACR-industry is often reactive or based on e.g., operation hours (scheduled/preventive). This results in a lot of labour-intensive work for troubleshooting and repairs, increased downtime, increased costs, and that systems operate inefficiently for long periods of time, as none of them is based on condition. One of the reasons to this is the focus on alarms rather than early warnings.

By analysing system performance with ClimaCheck deviations causing these problems can be automatically identified long before they cause the breakdown and generates an alarm. This makes it possible to move away from reactive maintenance, which have changed many industries and will affect the HVACR-industry fundamentally as well.

Early Warnings vs Alarms

To work efficient and cost efficient with maintenance it is important to act early, to avoid costly repairs. This is where the differences between early warnings and alarms is fundamental, as alarms in general are reactive. Some general differences between alarms and early warnings:

Alarms

- They are reactive, indicating that a problem has already caused a severe impact/failure.

- Their purpose is to prompt immediate action to address an existing fault.

- Typically indicate a critical issue that requires urgent attention.

- Usually based on data crossing a predefined threshold. Generated when e.g., a pressure, current or temperature goes outside a limit.

- Require immediate response to prevent downtime or further damage.

- Often lead to unscheduled, emergency maintenance or immediate intervention.

- Can lead to significant operational interruptions if critical issues are not addressed promptly.

- While necessary, they can lead to higher costs due to the urgent nature of the required actions, especially if they result in downtime or major repairs.

Early warnings

- They are predictive and signal a deviation with potential to cause a problem – before it becomes critical.

- Their purpose is to allow proactive measures to prevent a fault.

- Indicate a deviation from the norm that may not yet be critical but warrants attention.

- Based on deviations in performance (Often based on trend analysis and predictive analytics.)

- Provide a longer window for response and corrective action.

- May lead to maintenance or adjustments to prevent faults.

- Designed to minimise impact on operations through planned interventions.

- Provide information on trends that could lead to a problem.

- Help to optimize maintenance costs by avoiding unnecessary checks and reducing emergency interventions.

- Can be triggered by multiple factors

Based on these differences it is easy to conclude that when early warnings are configured, the number of alarms and downtime will be drastically reduced.

Experience shows that few systems are commissioned in a way taking different load and operating conditions into account. In most sites there are immediate savings offered by re-commissioning the site based on information made available through ClimaCheck performance analytics.

The ClimaCheck method and Guide

Changing business as usual isn’t easy, but in this case, it will be necessary as it will reduce energy consumption, save money and create a more sustainable organisation. ClimaCheck has offered performance analysis since 2004 and connected the first HVACR unit in 2007 to ClimaCheck online. Since 2004 over 100-man years of work have been spent on developing the platform, making it a unique tool.

The ClimaCheck method is verified by multiple agencies such as Research Institutes of Sweden AB (RISE earlier SP) International Energy Agency (IEA – Annex52) and National Renewable Energy Laboratory (NREL – Provider and User Perspectives on Automated Fault Detection and Diagnostic Products for Packaged Rooftop Units).

All this experience is channelled into our platforms which means you can get access to performance analysis on any Heat pump, Refrigeration or Air Condition system today. We have prepared a free guide to Predictive maintenance for HVACR that you can access here, which will guide you implement Predictive Maintenance.

Conclusion – a paradigm shift is inevitable!

For organisations owning or relying on HVCAR systems, Automated Fault Detection and Diagnostics coupled with Predictive maintenance, isn’t just a milestone – it’s a revolution in operational efficiency, energy conservation, and sustainability.

With Automated Fault Detection and Diagnosis, it is much easier to ensure optimal system performance and simultaneously contribute positively to global sustainability efforts. It’s not just an upgrade; it’s a complete transformation of how we maintain and manage these critical systems.

For service providers and companies’ offering to maintain HVACR system, it will be essential to work with Predictive Maintenance and AFDD to stay competitive. As the market will demand optimised and reliable systems which isn’t feasible with scheduled maintenance. A new level of service will need to be offered, as PdM/AFDD optimises the ways of work.

For companies that does not change, we have seen historically with companies like Nokia and Kodak, what happens..

Meanwhile, “equipment owners”, utilising heat pumps, chillers and air conditioning units also need to adapt/change. They need to request new levels of services, that ensures optimal performance 24/7 to avoid continued waste of money and energy.

The transformative potential of AFDD technology is evident, and its adoption will continue to grow as businesses and industries worldwide recognise its far-reaching benefits.

Do not hesitate to contact us if you want to get started

More news

Få ut mer av din mätutrustning och förbered dig inför vintersäsongen med ClimaChecks höstkampanj!

Under året har vi sett flera projekt (Max Hamburgare & Spacergy och Vasakronan är två tydliga ...

Important information from ClimaCheck: changes to early warnings via SMS

For almost 20 years, chillers and heat pumps have been connected to ClimaCheck online. Today ...

Viktig information från ClimaCheck; förändringar kring tidiga varningar via SMS

I snart 20 år har kylmaskiner och värmepumpar kopplats upp till ClimaCheck online. Idag är ...