How efficient troubleshooting saves money and energy in HVACR systems.

In recent publications and news, we have discussed the common savings potential of 10-30% in air conditioning, refrigeration, and heat pump (HVACR) systems when energy optimisation and predictive maintenance is introduced. However, these savings do not take soft savings as reduced failure cost and downtime into account.

To ensure that the savings are maximised, it is crucial that the troubleshooting of the HVACR system is efficient. ClimaCheck’s performance analysis is the most powerful tool for troubleshooting as well as predictive maintenance on the market. However, some of the benefits are rarely discussed individually, until now.

Time is money and effective troubleshooting of HVACR systems saves time.

It is essential to reach savings fast and keeping the costs low doing so, in order to shorten the ROI in any project. Therefore, energy optimisation applied on already existing systems are very cost-effective. By using performance analysis when troubleshooting HVACR systems, the process to identify problems will be efficient and savings can be reached faster.

The conventional method to troubleshooting HVACR systems.

Overheated compressors

When a HVACR system trips or there is a problem that causes complains, it will trigger a troubleshooting activity. It often consists of a technician going to site to control what the problem is.

Arriving to the site, one of the first actions is to reset the system (since it has tripped) and see what happens. As the system has been at stand-still, it is far from the operating condition when it tripped. Therefore, it can be challenging to guess what the original cause was.

If the system starts as expected and there is no obvious problem it will, in many cases be written off as a nuisance trip/false alarm. So, the actual problem is not identified or fixed (until it reoccurs and it becomes critical to fix it).

This often leads to unstable operations over long time, with increasing costs for both energy and service.

Performance analysis: a modern method to find problems.

It takes about 30 minutes to connect ClimaCheck (on a basic system) and once it is started, the performance information will immediately be available on the PC or in the Cloud (more about this later).

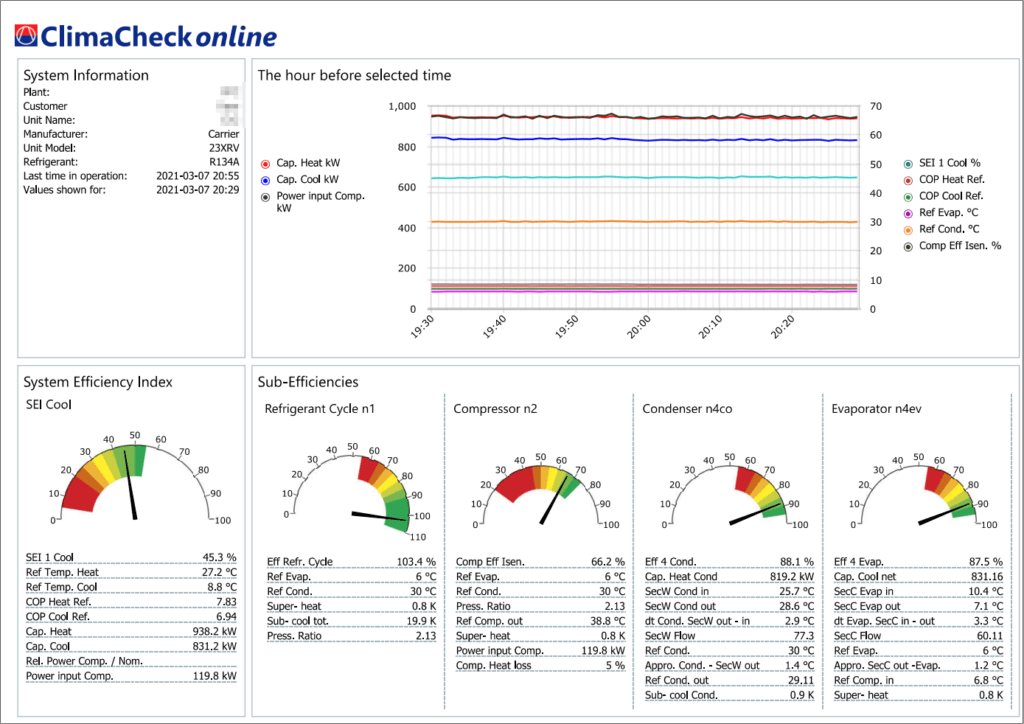

When the air conditioning, refrigeration or heat pump system is running, ClimaCheck will analyse the performance and deviations. It does so on a level of detail that no other system on the market does. Any deviation will be noticed directly on the screen pinpointing problems affecting performance. This will enable the technician to fix the actual problem instantly.

Timing is essential.

The similarity of both methods described above is the timing; they are reactive. When it comes to troubleshooting in HVACR system (after a system has tripped or do not/cannot maintain desired temperature), it is critical to find the cause. One of the challenges is to detect control-related problems or intermittent external system problems affecting the unit at certain specific operating conditions.

Measuring during the occurrence of the problem that caused the system to trip, takes time and drives up the cost as well as frustrations.

When data is collected during a site visit when the problem is not actively occurring at that specific time, the data collection will likely miss the flaws. This is often the case, due to the nature of reactive troubleshooting.

How much time is needed to measure performance?

One way to handle this is to leave the ClimaCheck onsite for some time at the site. That will increase the possibility of recording the problem. Please bear in mind that before the problem is identified it can be difficult to predict how long it will take for it to appear.

This brings in the time aspect. Analysing performance over short periods of time have its limitations. Because of this it makes the answer to the question “how long do we need to analyse a system to troubleshoot or optimise it” hard to answer.

The main reason is that it depends on many different factors of which you do not know of, until you have measured them. Thus, it is extremely cost-effective to continuously collect and analyse data. So, when a problem appears you can see exactly what happened during that specific time.

All necessary performance information available in one view.

Troubleshooting HVACR systems with the time on your side, is energy optimisation.

Scheduled measurements (as a part of preventive maintenance) may be the only realistic option on smaller systems that aren’t connected to the internet. However, as soon as you have larger systems (over 20-40 kW power input) it is a no brainer to continuously analyse performance.

The goal should be that the system never trips. This mindset will change the nature of troubleshooting as well as “business as usual”.

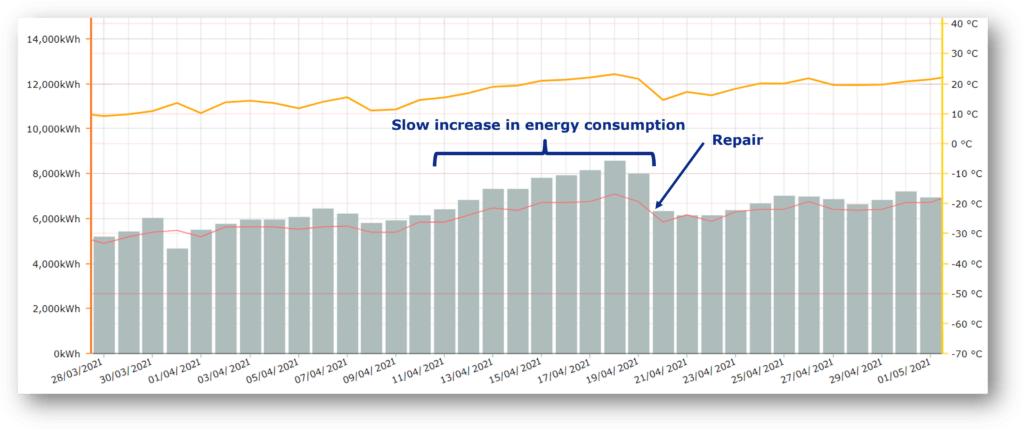

When performance is continuously analysed almost all deviations are found long before they cause a failure. It enables an early warning to be sent long before the alarm of system failure is generated. Moreover, the right person will get a notice that something needs to be fixed to avoid future failures.

Change is needed to be efficient.

By changing troubleshooting from something reactive to being based on actionable information, the technician who goes to site can be equipped with the suitable tools and spares. This makes the task more of a planned optimisation process rather than urgent and stressful work. Which often is performed under the pressure of damage to perishable goods and bad working conditions while the reputation of the business is dependent on the equipment functioning correctly.

The troubleshooting will not disappear, but the stage where it is performed is moved from after the failure to before. It will be based on complete system information by experts who are collecting and compiling experience from hundreds, or thousands of sites supported by advanced fault detection algorithms on a server with data from thousands of systems. This brings many benefits, the main is of course that breakdowns as well as performance drift is avoided.

Another possibility might not be as obvious, and it is about resources. Going to a site and spending hours and/or days trying to find a problem is time consuming and frustrating for technicians/engineers as well as equipment owners. Especially in an industry that is under constant pressure due to the lack of qualified technicians.

The golden opportunity!

The opportunity to monitor performance on hundreds of systems with less man hours will change service and maintenance in the HVACR industry. The companies willing to change from the conventional reactive maintenance will be able to build up services based on the new opportunities.

These services will meet the expectation of equipment owners who need to ensure energy efficiency in all their systems. This is also in line with the growing desire to get pay-back on all investments done in BMS/BAS/SCADA systems, with installation of large number of sensors to collect data.

Today many companies experience that they have huge amounts of data. However, the failures and maintenance continue as before. This will change when companies realise the potential of analysing data and getting useful information from cloud-based services such as ClimaCheck online to perform and offer cost-effective services.

Do you want to know more, feel free to Contact Us or follow us on LinkedIn to not miss any updates.

More news

Partner Spotlight: Neena Gill on the Climate Hero Club Podcast

In the episode, Neena shares her ClimaCheck experience and insights on why improving HVACR efficiency is one of the fastest and most cost-effective ways to reduce energy use and emissions.

World Refrigeration Day 2025 – Technology, Climate Action and an Industry Progressing into the Future.

June 26th marks World Refrigeration Day, a day to recognise the technology that enables life as we know it.

Office Hours During Midsummer Celebrations and the Summer

We wish you a joyful Midsummer celebration filled with happiness