-200 000 kWh/year

– $20 000 /year

10% to 20% savings per chiller

Chillers operate best with help from ClimaCheck

By monitoring the operations of the chillers with ClimaCheck, we identified problems with each chiller. Two chillers had low refrigerant levels and the third had an inlet guide vane (IGV) control issue. Two months after our initial discovery of these issues, ClimaCheck identified an IGV issue with another chiller.

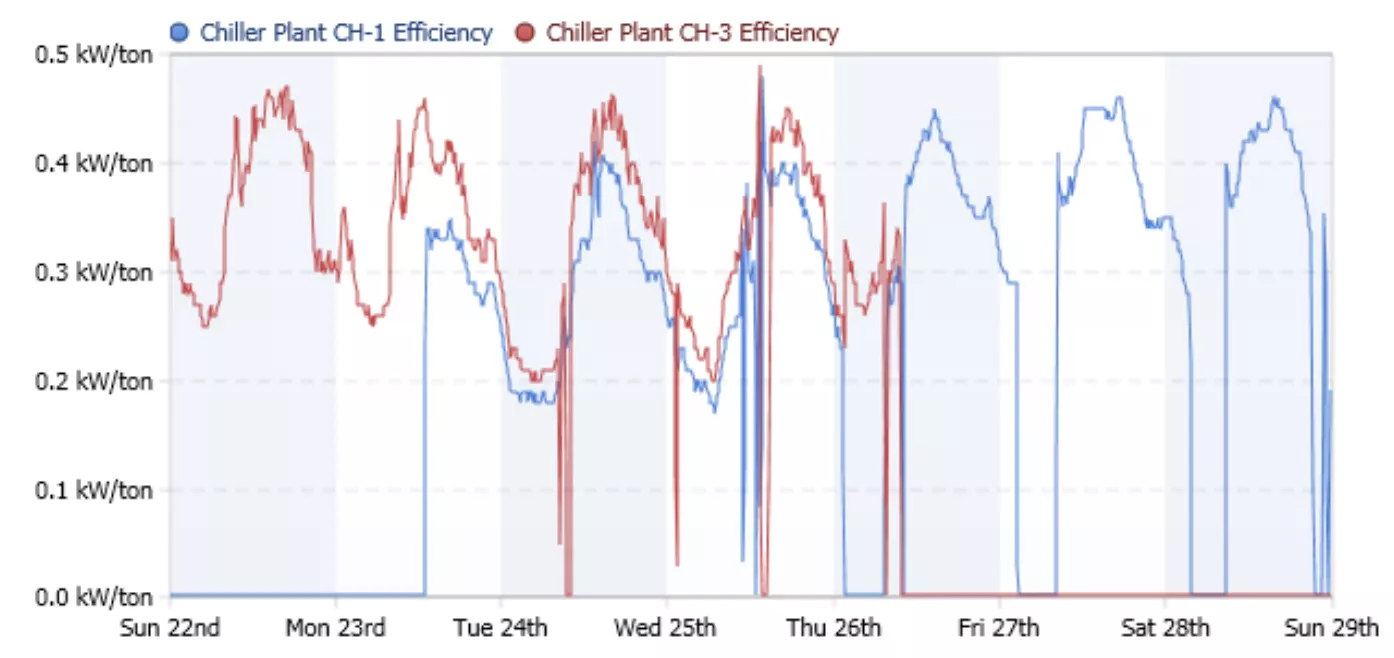

In early April, Chiller 1 was 10-15% less efficient than Chiller 3. It was found that the culprit of this discrepancy was low refrigerant. By adding 550 lbs of refrigerant, Chiller 1 performed 15% better than Chiller 3 as observed both by chiller efficiency and refrigerant temperatures. Similarly, ClimaCheck detected a refrigerant leak in Chiller 3. The leak was repaired and 350 lbs of refrigerant was added.

ClimaCheck identified issues with Chiller 2 – its efficiency went from being better than the two other chillers to worse as the loads changed. The IGV actuator had failed, preventing the chiller VFD from modulating properly. *expected savings After the IGV actuator was replaced, Chiller 2 was able to maintain chilled water temperature setpoint and saw an improved efficiency.

These three chillers use a combined 1.2 million kWh/year so it was integral to the medical center’s chilled water plant efficiency and utility costs to correct these issues. With the help of ETC, Ironwood Medical Center has more reliable chillers, effectively reducing the risks of summer outages in the Phoenix area.

Other projects