Predictive maintenance, only benefits!

You cannot change the weather – but you can avoid breakdowns in the chiller, during heatwaves! When a breakdown happens, it is too late!

All other days it is possible to work with predictive maintenance. Summer is approaching and for many companies, this means stressful days with failing chillers. However, most of these breakdowns happens completely unnecessarily! Almost all problems/deviations can be detected before it causes a failure if the performance of the chiller is analysed with ClimaCheck.

The increased number of breakdowns during heat waves results in plant owners being without emergency help as there is not enough technicians to perform emergency service at the same time everywhere. This results in e.g. hospitals having to cancel operations when air conditioning and dehumidification do not perform, destroyed food in grocery stores, and properties that cannot maintain the level of comfort due to failing chillers.

Performance analysis reduces stress and breakdowns.

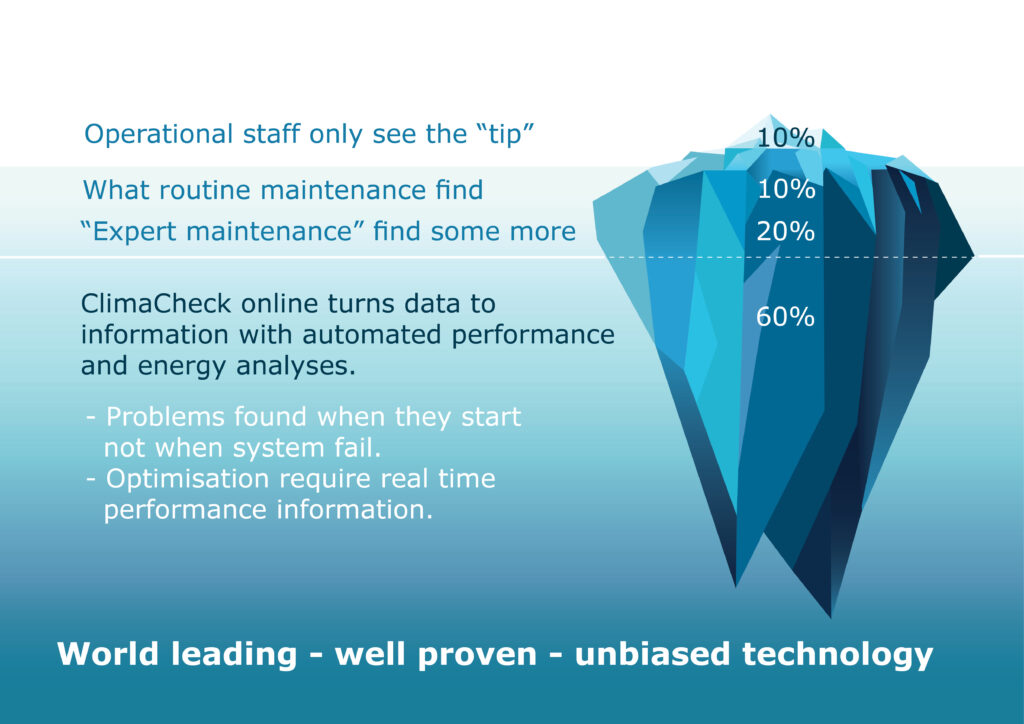

When system performance is analysed in real time, it becomes possible to act on changes/deviations when they occur. This is precisely what distinguishes predictive maintenance from preventive maintenance (scheduled) or reactive maintenance. Predictive maintenance is based on the condition of the HVACR-system, when a deviation occurs it can be fixed before it causes problems. Taking performance for granted will result in breakdowns and high energy consumption!

Predictive maintenance, only benefits!

Predictive maintenance is based on the needs and state of the HVACR-systems and measures are taken before deviations causes problems. Therefore, introducing predictive maintenance into an organisation requires new methods, which involves a cost. But the short-term and long‑term gains should motivate everyone who owns or works with chillers to embrace predictive maintenance. By avoiding failures, it is possible to avoid unplanned downtime. And in many cases save thousands of euro, since repairs, loss of production, comfort or goods is expensive.

The above “situation” is unfortunately not uncommon, it temporarily saves the situation. But it damages the unit and does not fix the cause of the problem, instead it risks to creating new ones.

Energy optimisation a prerequisite for predictive maintenance.

To be able to work efficiently with predictive maintenance and optimisation on chillers and heat pumps. The first step is to ensure good performance and operation in all different operating conditions, based on the information the performance analysis provides. When the optimisation is done, it is possible to work predictively and automatically detect, for example, reduced efficiency somewhere in the system.

Experience show that it is possible to reduce electricity consumption by 10-30% by optimising performance based on ClimaCheck’s performance analysis.

If you want to know more about the opportunities your company have, contact Niklas@ClimaCheck.com.

If you are curious about predictive maintenance and the possibilities with performance analysis. You can read this case “UNCOVER HIDDEN ENERGYSAVINGS” from ETC Group.

More news

Partner Spotlight: Neena Gill on the Climate Hero Club Podcast

In the episode, Neena shares her ClimaCheck experience and insights on why improving HVACR efficiency is one of the fastest and most cost-effective ways to reduce energy use and emissions.

World Refrigeration Day 2025 – Technology, Climate Action and an Industry Progressing into the Future.

June 26th marks World Refrigeration Day, a day to recognise the technology that enables life as we know it.

Office Hours During Midsummer Celebrations and the Summer

We wish you a joyful Midsummer celebration filled with happiness