What is the difference on a conventional SCADA/BMS and ClimaCheck?

One of the most common questions/comments we get is; Why do we need ClimaCheck’s performance analyse when we already have “all” the data and values in our BMS/BAS/SCADA-system. In other words “what is the difference on a conventional SCADA/BMS and ClimaCheck”

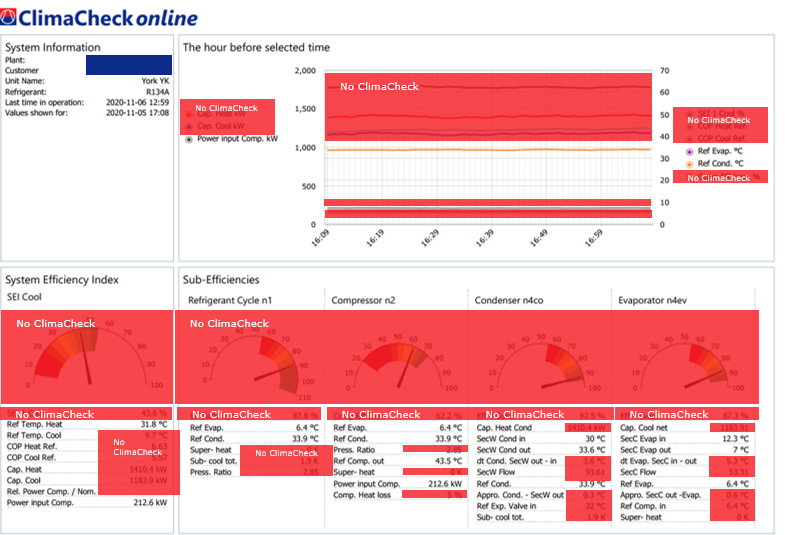

To answer this, it is very important to understand the difference between data and information. Many HVACR systems, Building Management systems (BMS) and Supervisory control and data acquisition (SCADA) systems collect data, so do we. But without proper analysis, knowing the temperature, pressure, or the power consumption is not too helpful as they vary continuously over a wide range. With data points it is basically only possible to work with reactive or scheduled maintenance. Which does not predict nor prevent failures!

ClimaCheck turns data into information!

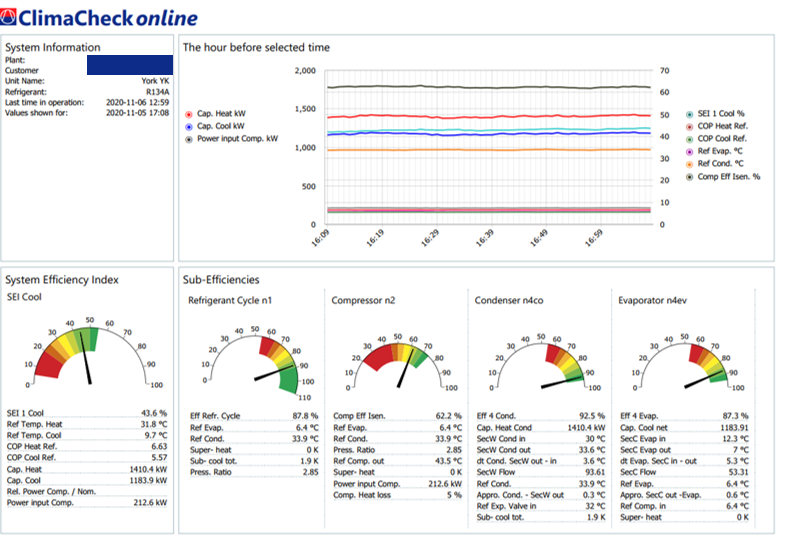

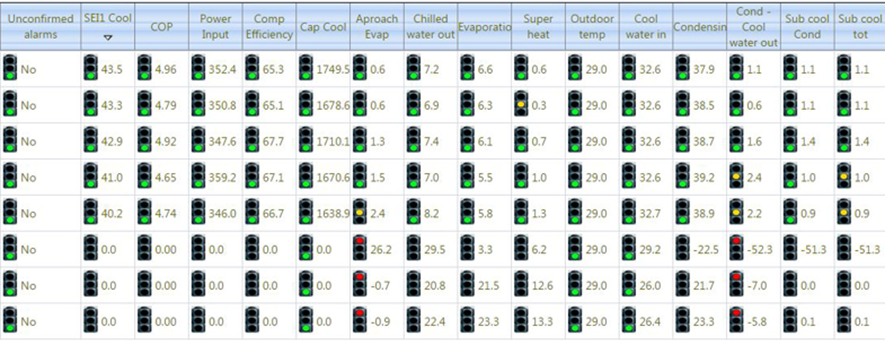

By “adding” performance analysis, everything changes. Decision based on information/KPIs such as system efficiency index (SEI) and sub efficiencies make it possible to work cost effectively with predictive maintenance and energy optimisation. In many cases this can be done without adding sensors, since they are already there.

With experience from thousands of systems, we know that it is possible to save 10-30% of the electricity in most HVACR systems. As well as most of the breakdowns can be prevented, when early warnings are active. And component deterioration will be exposed, during unfavourable operating conditions.

By analysing performance with ClimaCheck it is possible to automatically identify problems as well as saving opportunities, quicker and with higher quality (more cost-effective) than with conventional systems. It is also possible to minimise the number of false alarms/call-outs. ClimaCheck can communicate with most BMS/BAS/SCADA-systems. So when data is collected, ClimaCheck can analyse it. If the necessary data isn’t collected, we can supply additional sensors if needed.

Why performance analysis from ClimaCheck is a game changer for the optimisation of HVACR systems:

- More efficient maintenance with less time spent in all stages.

- Possible to work efficient with energy optimisation and get confirmation on improvements in real time.

- Predictive Maintenance – Possibility to fix problems before they cause breakdowns.

- Use staff, resources, and skills more efficient in the organisation.

- Simplified visualisation of performance with System Efficiency Index (SEI) and sub-efficiencies. As well as monitoring/presentation of COP, effects and flows more cost-effectively than possible with conventional methods.

- Detailed energy statistics that show deviations and where the cause can be found at component level in the ClimaCheck software or ClimaCheck online.

We hope this article answered your questions on the difference on a conventional SCADA/BMS and ClimaCheck system and analysis. ClimaCheck have helped many organisations around the world to save large amount of energy. If your organisation is ready to add your HVACR systems to the industry 4.0 revolution, and be more sustainable don’t hesitate to contact us?

Contact Niklas.Berglof@ClimaCheck.com for more information!

More news

Få ut mer av din mätutrustning och förbered dig inför vintersäsongen med ClimaChecks höstkampanj!

Under året har vi sett flera projekt (Max Hamburgare & Spacergy och Vasakronan är två tydliga ...

Important information from ClimaCheck: changes to early warnings via SMS

For almost 20 years, chillers and heat pumps have been connected to ClimaCheck online. Today ...

Viktig information från ClimaCheck; förändringar kring tidiga varningar via SMS

I snart 20 år har kylmaskiner och värmepumpar kopplats upp till ClimaCheck online. Idag är ...