Why it is worth to invest money on Measuring and Verification of your equipment!

Today huge amounts of money are invested in top of the line heat pumps, refrigeration and air conditioning systems, to save energy. But is this enough?

Sadly, it isn’t, and we repeatedly measure new (and old) equipment where 20‑30% energy is wasted. That is why we always recommend that ClimaCheck is installed from the start and used for the commissioning of your cooling system or heat pump, to ensure that it is optimised for your specific system, load and climate which is not the same as any other project. Thereafter, a structure for predictive maintenance should be established.

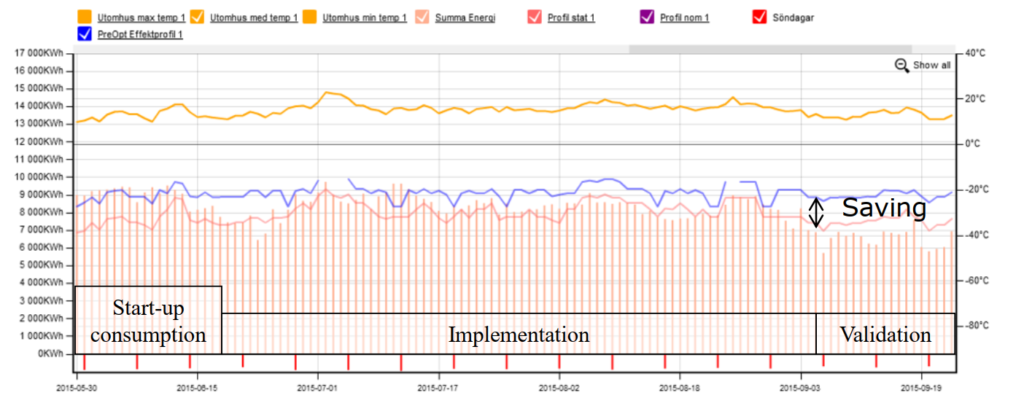

The energy graph shown below is a top of the line installation of two chillers and two heat pumps that is supplying a new data center with cooling. The heat is delivered to a local district heating network.

Yellow line – Outdoor temperature

Red bars – Energy consumption per 24 hours

Blue line – Energy consumption based on energy signature before optimisation (=predicted consumption)

Red line – Energy consumption based on energy signature after optimisation

Result – Savings of 2400 kWh/day (26% less energy consumption)

During the verification phase (see picture) another calibration was done and even more energy savings was possible. Today many companies focus is on state-of-the-art equipment and green energy which is good. But the possibility to save almost 30% energy is usually overlooked, many times due to challenges in the communication and lack in good way show the performance of the cooling systems and heat pumps.

To measure is to know

More news

ClimaCheck online – Maintenance – 6-7/7

During this weekend (sixth and seventh of July), ClimaCheck online will be through some planned maintenance.

HVACR optimisation and the potential reduction of CO2!

Multiple organisations have evaluated the saving potential within HVACR optimisation, and reached similar conclusions: it is possible to reduce CO2 emissions by millions of tons by optimising HVACR systems.

Midsummer celebration and information on our office hours for the Summer!

This special time of year brings us together to enjoy the light, dance around the Maypole, and welcome the summer!