Why opening the “black box” finds new saving opportunities, time after time!

One of the main reasons that ClimaCheck finds saving opportunities of 10-30%+ in basically every system that is analysed is the unique analysis. The analysis is basically an EKG for air conditioning, refrigeration, and heat pump systems and the benefits are as significant for our industry as EKG was for analysing heart problems.

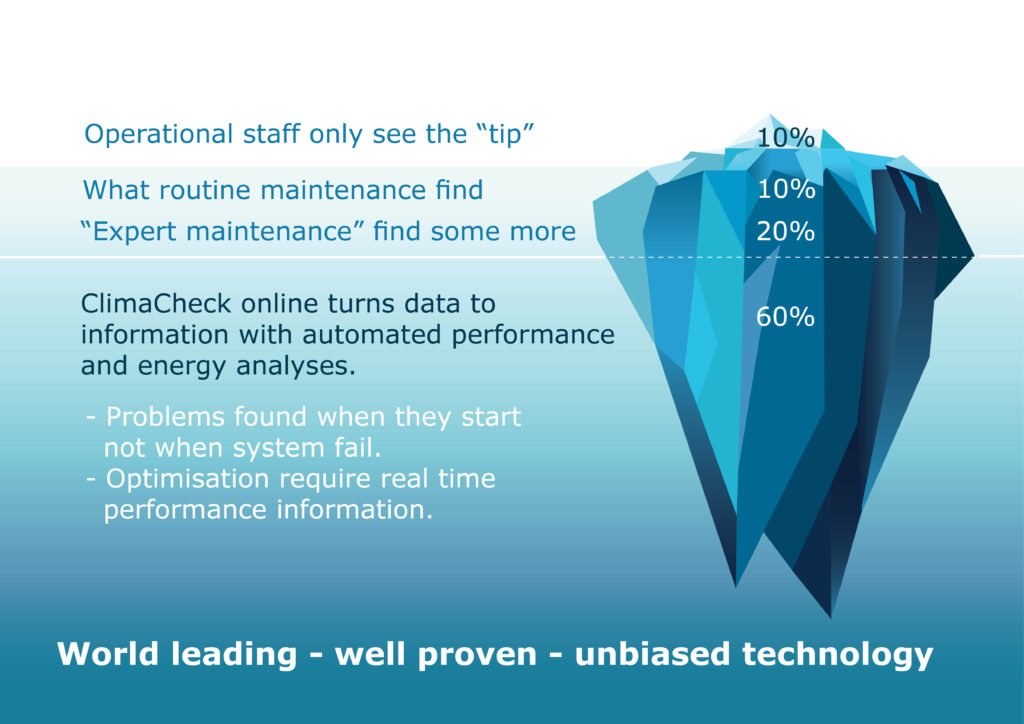

By “seeing” into the system in a way that isn’t possible with conventional methods, new saving opportunities surface. You can compare the difference with a doctor that listens to the heart compared to a doctor who performs an EKG; some problems can be found by listening while the EKG will give much more information.

Compared to conventional BMS and SCADA systems that log and show temperatures and pressures ClimaCheck perform a complete thermodynamic analysis of the vapor compression cycle wich today is a well-proven and cost-effective method to optimise HVACR systems. The analysis identifies many saving opportunities, that have been missed in conventional BMS and Scada system and scheduled maintenance.

What can ClimaCheck “see”?

The actionable information that the ClimaCheck analysis provides is the key to many of the opportunities. To work efficiently with energy optimisation and predictive maintenance, a high level of information is needed. Such as:

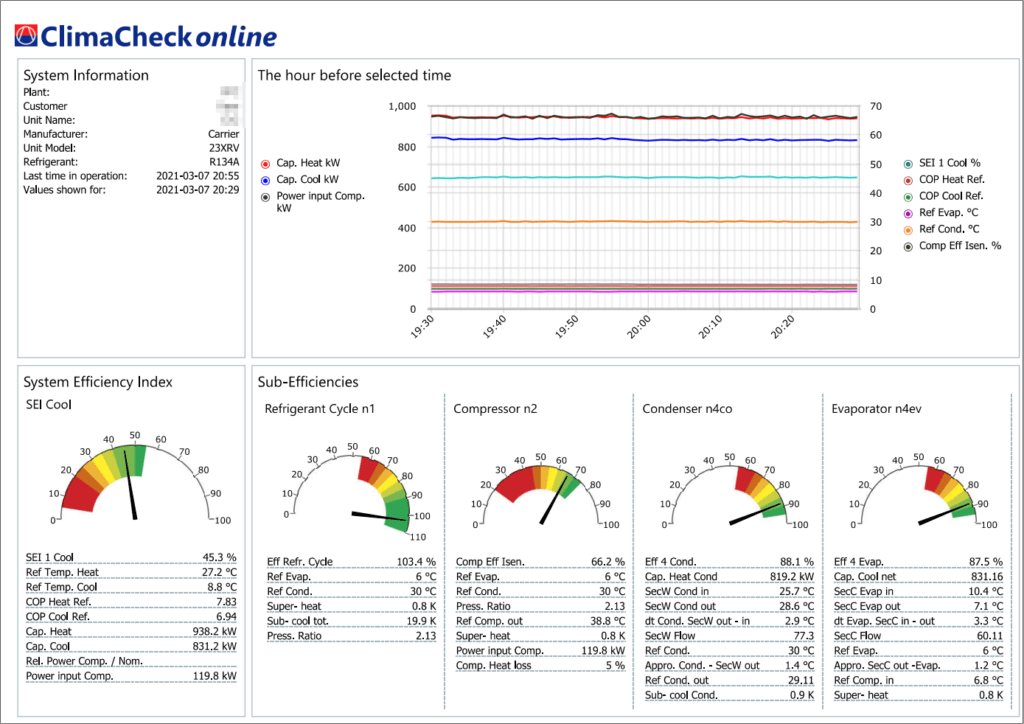

- System Efficiency Index “SEI”

- Sub-efficiencies of compressor, condenser, and evaporator

- Energy signature with baseline and expected consumption

- Cooling and heating capacity

- Total energy consumption for the compressor

- Expansion valve function (superheat values)

- Refrigerant charge/leakage

- Early warnings for deviations in performance

- Early warnings for pressure, temperature, power outside the envelope

- Inlet/Outlet temperature, temperature difference, power input

- Flow on secondary media (water/air/brine) (no flow-meter necessary)

When this information is available the optimisation work can start. However, getting to this position can be a process, therefore we have made this guide, which will help reach this point.

Energy optimisation and Energy efficiency is possible when the right information is available.

One part of the ClimaCheck analysis is that it continuously analyses system performance. Therefore, it is possible to monitor if the energy is used efficiently or not during every specific operating condition and load. This is a crucial difference from e.g. COP (ClimaCheck calculate this as well), which needs additional calculations to tell whether it is good or not during the specific operation.

When there is a deviation in performance, the dashboard will clearly visualise where it is, and what component is underperforming. This will also indicate whether a change in the system (controls, dirt, new loads etc) affects the Chiller and/or Heat Pump and decrease performance which will affect energy consumption negatively.

Given that the information is used to optimise the system, these two factors make it easy to ensure energy efficiency.

Predictive Maintenance

When energy efficiency is reached, it is important to maintain it by avoiding performance drift. This is done by configuring early warnings, that will report deviations in the performance when they happen. When this is done, it is possible to act based on the condition of the unit. For example, if the efficiency decreases in a compressor, it is possible to plan corrective measures (or plan actions) long before a breakdown.

Failures and inefficient operations lead to increased costs and CO2 emission. Using ClimaCheck for Indirect Leak Detection, it is possible to find small leaks that will lead to decreased efficiency over time. These kinds of leaks can take years to be found during preventive maintenance or routine services.

The necessary change to take care of potential saving opportunities

Is this easy? Yes and no. All the technology needed is available, and it is not expensive to get started. However, IoT, Sustainability, Predictive Maintenance etc, needs to be a part of “Business as Usual”. Just because new technologies are available doesn’t mean that you have them.

We commonly see this regarding Energy Optimisation and Predictive Maintenance. Equipment owners think they have bought one kind of service when they, in actuality, have bought something else. To get something, it needs to be requested in the right stage of the procurement process.

Regardless of where you are in the process, maybe you are buying a new HVACR system or planning to optimise one you have. ClimaCheck can supply you with the documentation and information you need to ensure energy efficiency and to get Predictive Maintenance.

Don’t be discouraged if you feel that this is overwhelming. Data collection is a core function of ClimaCheck, and the system can work turnkey or be integrated with an already existing system. When integrated, it needs to be ensured that the necessary data points are available, if not it is usually easy to add the missing sensors.

Conclusion

The ongoing energy crisis forces an acceleration to reach savings faster than ever before. Companies that want to keep on with “Business as Usual” will be less sustainable, profitable and competitive compared to companies that embraces changes. Keeping up with this transformation is hard, necessary and luckily possible.

So, it doesn’t matter what your company’s situation is, ClimaCheck can help. We have experience from manly leading companies around the world, and thousands of HVACR systems. Therefore, we are used to work close to contractor and equipment owners to optimise HVACR system’s performance.

If you want to learn more, you can download our free guide to achieve new savings or contact us directly.

More news

Partner Spotlight: Neena Gill on the Climate Hero Club Podcast

In the episode, Neena shares her ClimaCheck experience and insights on why improving HVACR efficiency is one of the fastest and most cost-effective ways to reduce energy use and emissions.

World Refrigeration Day 2025 – Technology, Climate Action and an Industry Progressing into the Future.

June 26th marks World Refrigeration Day, a day to recognise the technology that enables life as we know it.

Office Hours During Midsummer Celebrations and the Summer

We wish you a joyful Midsummer celebration filled with happiness