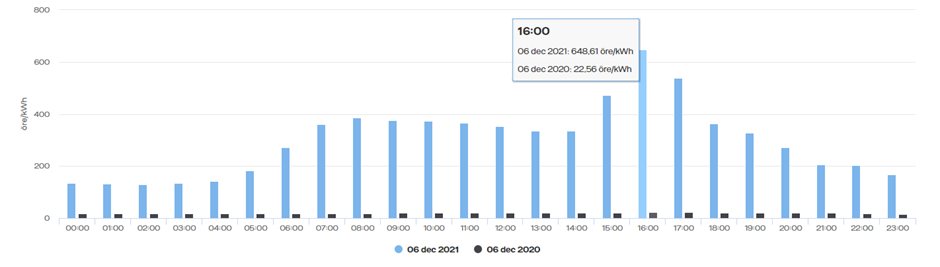

The price is what?!

Electricity prices is increasing across Europe. Sweden is no exception, this Monday (6/12) the price reached 0.6€ per kWh (648.61 öre/kWh). Which is a new record for Sweden! Those with fixed electricity price, won’t be hit by this record, short term. Nevertheless, it should be a wake-up call to ensure that all operations within the organisation are energy efficient.

Postponed or ignored projects to save energy are resulting in higher operation cost. For most companies, it is not an option to stop just because the electricity price goes up. So, the margins will decrease. The option to reduce the electricity consumption before the price went up this time, was missed. Better late than never – the potential did not disappear just because the price goes up – the ROI only gets shorter.

This raises the question: whether it is the money or the will to be sustainable that will be the primary driver for energy efficiency. However, that is a discussion for a rainy day…

The best kWh is the one that wasn’t used.

At this point it doesn’t matter whether the electricity is green or not, the goal should be to decrease the consumption. Not claiming the electricity is “green” and keep on as before. So, what can be done before the electricity price goes up next time?

In many buildings the refrigeration, heat pump and air conditioning (HVACR) systems are the largest electricity consumer (30-60%). However, the efficiency is rarely questioned if the desired temperature is reached.

ClimaCheck analyse thousands of systems and even if the desired temperature is reached, we rarely find systems that runs perfect at the start of the performance analysis. Normally it is possible to save between 10-30%!

Therefore, it is crucial to initiate projects that implement performance analysis and enables propper energy optimisation.

Multiple benefits, results in a short ROI

Energy savings isn’t the only benefit when performance analysis is introduced, deviations will be noticed before there is a noticeable impact in cooling or heating. Which makes it possible to fix them before a breakdown, this is called “predictive (condition based) maintenance”. For many organisations this is a new methodology of work, so it will need changes. However, it has a very short ROI, almost always less than 2 years! Many times, it can be much shorter as problems are identified and corrected before the energy consumption increases or a systems failure. Avoiding a breakdown/failure often pays for the whole investment that enabled predictive maintenance, instantaneously.

Acceptance is key!

Understanding that reaching the setpoint isn’t a good benchmark, is necessary to move on. Depending on where your organisation is today, you might need to start from the beginning with collecting data. Or you might be in a situation where you have a lot of data that can be analysed and transformed into actionable information.

When the information is available, it is important to set the framework on how it is used in the organisation. When this is done correctly you can be sure that your HVACR-system runs efficient with minimised risk of failures and complaints.

So, in the situation where the electricity price slowly is increasing (or during a sudden price peak) at least the HVACR-system won’t consume more electricity than necessary. The system will also have a lower risk to fail because of poor operation during heat waves or cold spells. The problems do not start during the extreme weather conditions they are generally there long before but pass unnoticed as setpoints are reached with reduced performance.

To get “all of this” benefits in your organisations you need to act. We are always eager to tell you more, fill out the form and we will contact you!

By accepting our newsletter (in the form) you will also get information when we release our guide to help organisation to take the next step to implement predictive maintenance to sustainability work.

More news

Partner Spotlight: Neena Gill on the Climate Hero Club Podcast

In the episode, Neena shares her ClimaCheck experience and insights on why improving HVACR efficiency is one of the fastest and most cost-effective ways to reduce energy use and emissions.

World Refrigeration Day 2025 – Technology, Climate Action and an Industry Progressing into the Future.

June 26th marks World Refrigeration Day, a day to recognise the technology that enables life as we know it.

Office Hours During Midsummer Celebrations and the Summer

We wish you a joyful Midsummer celebration filled with happiness