Do not take performance for granted!

Many equipment owners assume that their air conditioning and refrigeration equipment (HVACR-system) work well. As long as the desired temperature is maintained and a scheduled maintenance check, is performed.

Fact is that this has nothing to do with efficiency and little to do with reliability. The maintenance protocol does not document performance of the unit. Best case they will include a check of that heat exchangers are not fouled and that charge is sufficient for the operating condition that happen to occur when maintenance check is done.

Rarely are there any documentation beyond a list of values that do not give sufficient information to define the performance even during the conditions it is operating at or compare it with the KPIs specified for the chiller.

How the chiller operates in the system and handle different operating conditions and capacities is not something that can be identified by what is specified in most maintenance contracts.

It is assumed that a HVACR system maintaining temperatures and not giving alarms is efficient and nothing could be more wrong.

This pinpoints a major misconception in the HVACR-industry, where many equipment owners assume that as long as the desired temperature is reached everything works. Breakdowns, refrigerant leaks, and repeated alarms is business as usual. In many cases it is considered a part of the “HVACR-package”.

The fact is that most of the problems can be avoided with fewer breakdowns and decreased energy consumption as a result!

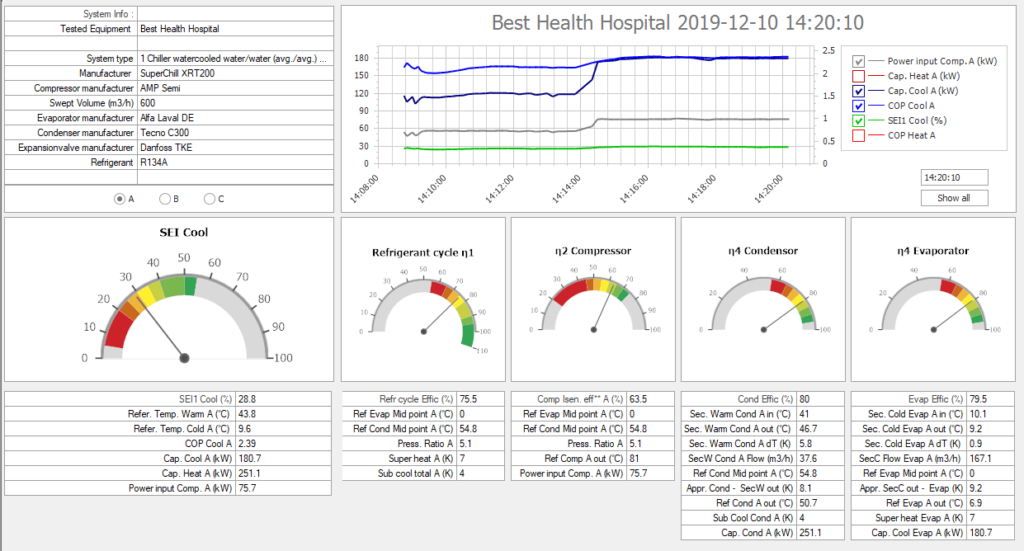

The key is to turn data into information!

We do not find systems that do not have any potential to save energy!

With more data available online than ever, it is possible to change Business as usual. Like many other industries have done over the last decade. It is time to embrace IoT and Industry 4.0 in the HVACR industry as well.

By analysing data and use the information, it is possible to significantly reduce cost of ownership with predictive maintenance and optimisation. We would like to go as far and say, if someone claims to work with optimisation without having documented information about performance their work could be more efficient. Because there is no way to know what should be done, or if measures/actions have the desired result if the performance was not analysed and documented before, during and after changes.

Our goal is to ensure that energy is used efficiently to reach the desired temperature! And we often see possibilities to reduce energy consumption with 10-30% in systems were nobody believe there is a problem

So, together with large property owners inside and outside Sweden we have developed “ClimaCheck certified systems” a service to help anyone who owns a HVACR-system to ensure it works as efficient as possible in their organisation!

You can find more information about the service here : ClimaCheck certified systems

Contact us or a ClimaCheck partner to get more information about ClimaCheck and our services.

More information about separate Certifications and services:

ClimaCheck support for predictive maintenance

Even more to read:

The Value of Fault Detection and MBCx For Chillers by Glen Anderson.

Collection of Cases and success stories

System Efficiency Index – The Game Changer by Klas Berglof

Is your company ready for the next heat wave? by ClimaCheck

More news

Partner Spotlight: Neena Gill on the Climate Hero Club Podcast

In the episode, Neena shares her ClimaCheck experience and insights on why improving HVACR efficiency is one of the fastest and most cost-effective ways to reduce energy use and emissions.

World Refrigeration Day 2025 – Technology, Climate Action and an Industry Progressing into the Future.

June 26th marks World Refrigeration Day, a day to recognise the technology that enables life as we know it.

Office Hours During Midsummer Celebrations and the Summer

We wish you a joyful Midsummer celebration filled with happiness